cleanroom projects

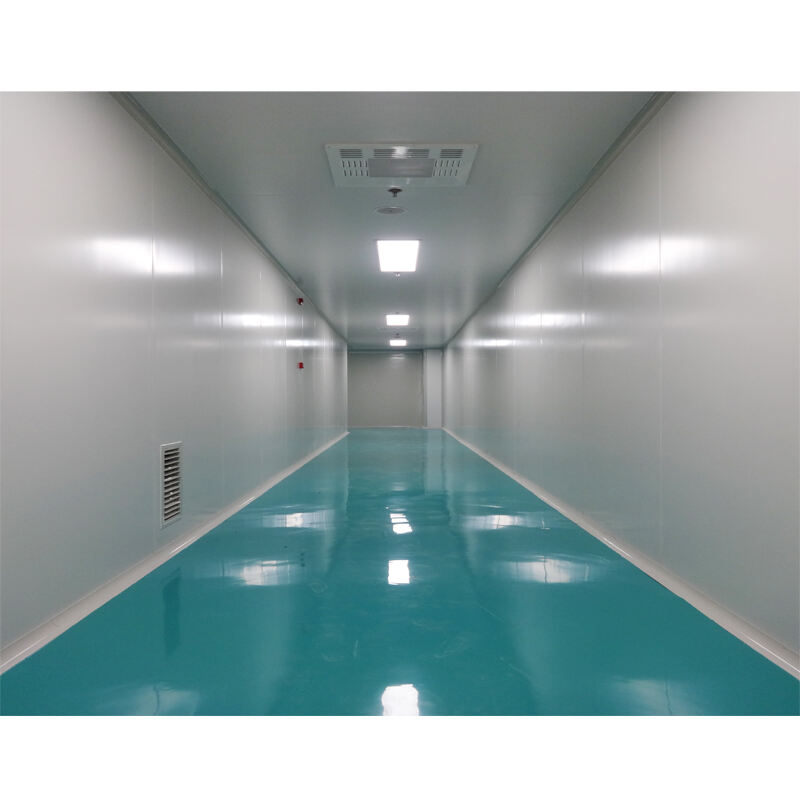

Cleanroom projects represent state-of-the-art controlled environments designed to maintain precise levels of particulates, temperature, humidity, and air pressure. These specialized facilities are engineered to meet stringent ISO classifications and industry-specific requirements, incorporating advanced HVAC systems, HEPA filtration, and sophisticated monitoring equipment. The projects encompass comprehensive design, construction, and validation phases, ensuring compliance with regulatory standards while maintaining optimal operational efficiency. Modern cleanroom installations feature automated environmental control systems, integrated monitoring solutions, and flexible modular designs that accommodate future expansion needs. They employ specialized construction materials and techniques, including antimicrobial surfaces, sealed lighting fixtures, and interlocked airlocks. These facilities serve diverse industries, from semiconductor manufacturing and pharmaceutical production to biotechnology research and medical device assembly. The projects include detailed consideration of personnel and material flow patterns, emergency protocols, and maintenance procedures, ensuring both operational efficiency and contamination control. With increasing demands for quality control and regulatory compliance, cleanroom projects have evolved to incorporate smart technology integration, energy-efficient systems, and sustainable design principles.