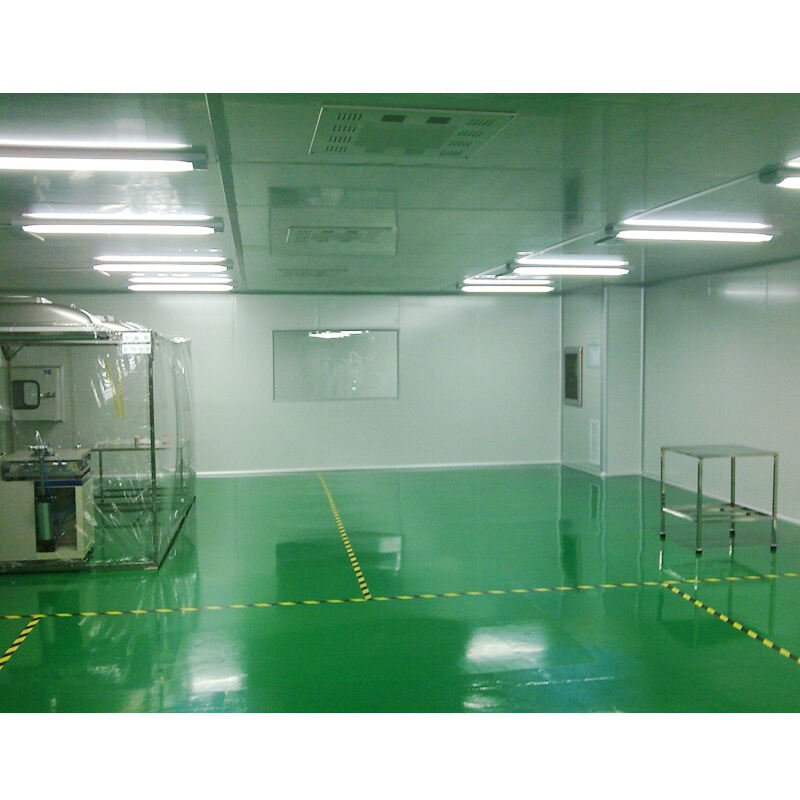

clean room in pharmaceutical industry

A clean room in the pharmaceutical industry represents a meticulously controlled environment designed to maintain exceptionally low levels of particulates, such as dust, airborne microorganisms, and chemical vapors. These specialized facilities are essential for the manufacturing, processing, and packaging of pharmaceutical products under stringent regulatory requirements. The clean room employs advanced HVAC systems with HEPA filtration to ensure air purity, maintaining specific pressure differentials and air change rates. The facility features seamless wall panels, specialized flooring systems, and airlocks to prevent contamination. Temperature, humidity, and particle counts are continuously monitored through sophisticated environmental monitoring systems. Personnel access is strictly controlled, requiring specific gowning procedures and protocols. The clean room classification system, ranging from ISO Class 1 to 9, determines the maximum allowable particles per cubic meter of air. Pharmaceutical clean rooms typically operate at ISO Class 5 to 8, depending on the product requirements. These facilities support various pharmaceutical operations, including sterile drug manufacturing, vaccine production, biotechnology processes, and quality control testing. The integration of automation and robotics further minimizes human intervention and contamination risks, ensuring consistent product quality and regulatory compliance.