Understanding Cleanroom Environments

A cleanroom is a specially designed controlled environment aimed at minimizing contamination and maintaining high levels of cleanliness. Used extensively in manufacturing industries, pharmaceuticals, and research facilities, cleanrooms are essential for ensuring that processes and Products meet stringent quality standards. These environments are characterized by their ability to control air pollutants like dust, microbes, and aerosol particles to ensure the precision and purity of operations and outputs.

The efficiency of cleanrooms is of paramount importance as it directly impacts product quality, operational costs, and adherence to regulatory requirements. For instance, compliance with industry standards like ISO 14644, which sets regulations for cleanrooms and associated controlled environments, ensures that facilities maintain optimum cleanliness and operational efficiency. With cleanroom efficiency closely linked to crucial aspects such as product reliability and compliance, organizations must prioritize maintaining these environments to avoid lapses that could lead to costly downtimes or non-compliance fines.

How Air Showers Operate

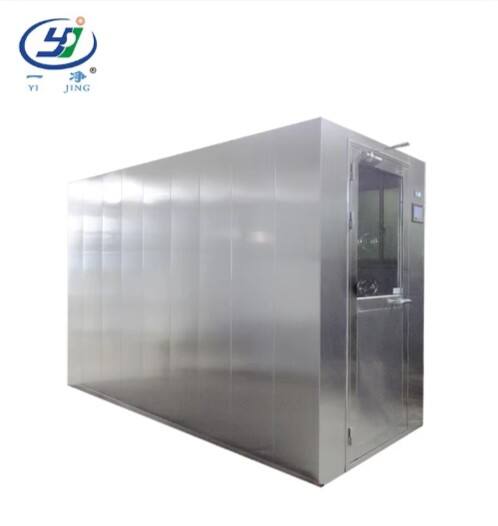

Air showers are critical components in maintaining the integrity of cleanroom environments by effectively removing contaminants. These systems operate by employing high-velocity jets of HEPA-filtered air, which dislodge dust and particulate matter from the clothing and surfaces of personnel. As individuals pass through the chamber, sensors detect their presence and activate powerful air streams. The air is directed towards their clothing in a scrubbing action, thereby minimizing the risk of contamination entering the controlled environment. This mechanism ensures that the cleanliness required for operations in industries like pharmaceuticals and biotechnology is upheld.

Key components of air showers contribute significantly to their effectiveness. Firstly, HEPA filters trap airborne particles during the decontamination process, ensuring that only clean air is recirculated. The airflow management systems are programmed to direct the air through adjustable nozzles placed strategically around the chamber. Moreover, control panels equipped with microprocessors manage the timing and intensity of airflow cycles, optimizing the cleaning process for each user. These elements collaboratively ensure that air showers perform efficiently and reliably.

When compared to other contamination control methods, air showers offer distinct advantages. While gowning rooms provide an initial layer of protection, they may not be sufficient for removing microscopic particles. Similarly, sticky mats at entry points capture only a limited amount of contaminants from footwear. Air showers, however, provide a more comprehensive solution by actively removing contaminants from all surfaces of an individual before they enter the cleanroom. This effectiveness makes them indispensable in industries where maintaining high standards of hygiene and cleanliness is paramount.

How Air Showers Improve Clean Room Efficiency

Air showers significantly enhance cleanroom efficiency by drastically reducing contamination levels. In cleanroom environments, even the slightest contamination can lead to extensive downtime, impacting overall productivity. By employing high-velocity air jets, air showers effectively remove particulate matter from personnel and equipment entering or exiting controlled areas. This not only minimizes contamination risks but also ensures uninterrupted operations, thereby maintaining high productivity levels.

To maximize the effectiveness of air showers, establishing optimal cleaning cycles and protocols is critical. Industry best practices suggest integrating air showers with regular cleanroom maintenance schedules to ensure consistently high cleanliness standards. Protocols might include specific air shower cycles per person or equipment passage and routine monitoring of filter and nozzle functionality. Such practices help sustain the efficiency of air showers while maintaining the integrity of cleanroom operations.

Moreover, air shower efficiency ratings are essential in determining their performance metrics. These ratings are typically evaluated based on factors such as airflow speed, measured in meters per second, and the number of air changes per hour in the air shower chamber. Higher airflow speeds and more frequent air changes generally indicate better contamination control capabilities. Understanding these metrics aids cleanroom managers in selecting suitable air showers that align with the specific cleanliness requirements of their operations.

Benefits of Using Air Showers

Implementing air showers in cleanrooms offers a compelling cost-effective advantage by significantly reducing contamination-related expenses. Initial investments in air showers translate to considerable savings over time, as these systems help prevent costly product defects and reduce the need for frequent cleanroom maintenance. By minimizing particulate infiltration, air showers also decrease the strain on HVAC systems and filters, leading to lower operational costs in the long run.

Furthermore, air showers contribute to long-term maintenance benefits by preserving the condition of cleanroom environments and equipment. They decrease wear and tear on cleanroom infrastructures, promoting an extended lifespan for technological and mechanical assets. Cleanrooms equipped with air showers experience less downtime due to contamination, ensuring uninterrupted operations and consistent productivity, which are critical for sectors such as pharmaceuticals and electronics.

Psychologically, cleanroom protocols, such as the use of air showers, positively impact staff morale and confidence. Employees become more aware of the importance of maintaining safety standards and feel secure knowing that the best practices are in place to ensure a contaminant-free workspace. This mindfulness towards cleanliness not only elevates individual responsibility but also enhances team cohesion and motivation, essential elements for maintaining high productivity and quality in controlled environments.

Industries That Benefit from Air Showers

Air showers are critically important in industries with stringent contamination control requirements, such as the pharmaceutical and biotech sectors. In these industries, maintaining compliance with regulatory standards is essential, and air showers offer a reliable method to minimize particulate contamination before it enters controlled environments. By doing so, they help ensure product safety and purity, critical factors in pharmaceutical and biotech manufacturing where the slightest contamination could compromise product efficacy or lead to significant financial losses.

Furthermore, in the microelectronics and aerospace industries, even minute contamination can lead to considerable failures, underscoring the importance of air showers. In microelectronics, particles as small as a few microns can wreak havoc on circuit functionality, while in aerospace, contamination can affect both component safety and performance. Thus, air showers serve as a first line of defense, ensuring that such high-stakes environments remain as contaminant-free as possible, supporting high quality and reliability standards.

Laboratories and research facilities also significantly benefit from air showers. These environments often handle sensitive experiments where even the slightest contamination could skew results and impair research integrity. By deploying air showers, these facilities can maintain a controlled environment, thus ensuring the accuracy and reliability of experimental outcomes. This contamination prevention is pivotal to advancing research without the interference of external variables, ultimately contributing to more innovative and reliable research outputs.

Best Practices for Implementing Air Showers

Implementing air showers effectively requires careful attention to several key practices. Firstly, training personnel on the proper use of air showers is crucial. This ensures that the showers are used correctly, maximizing their effectiveness and contributing to overall cleanroom efficiency. Secondly, integrating air showers into the cleanroom design at the outset is advisable. This strategic placement enhances workflow and significantly minimizes contamination risks. Lastly, regular maintenance and upgrades of air showers are essential to ensure they operate at peak efficiency. This not only prolongs their lifespan but also sustains their effectiveness in maintaining cleanroom integrity.

FAQ

What is the purpose of a cleanroom?

A cleanroom is designed to minimize contamination and maintain a controlled environment, essential for high-precision industries like pharmaceuticals and manufacturing.

How do air showers contribute to cleanroom efficiency?

Air showers use high-velocity air jets to remove contaminants from personnel and equipment, reducing contamination risks and enhancing cleanroom efficiency.

Which industries most benefit from air showers?

Industries like pharmaceuticals, biotechnology, microelectronics, aerospace, and research facilities benefit greatly from the contamination control offered by air showers.