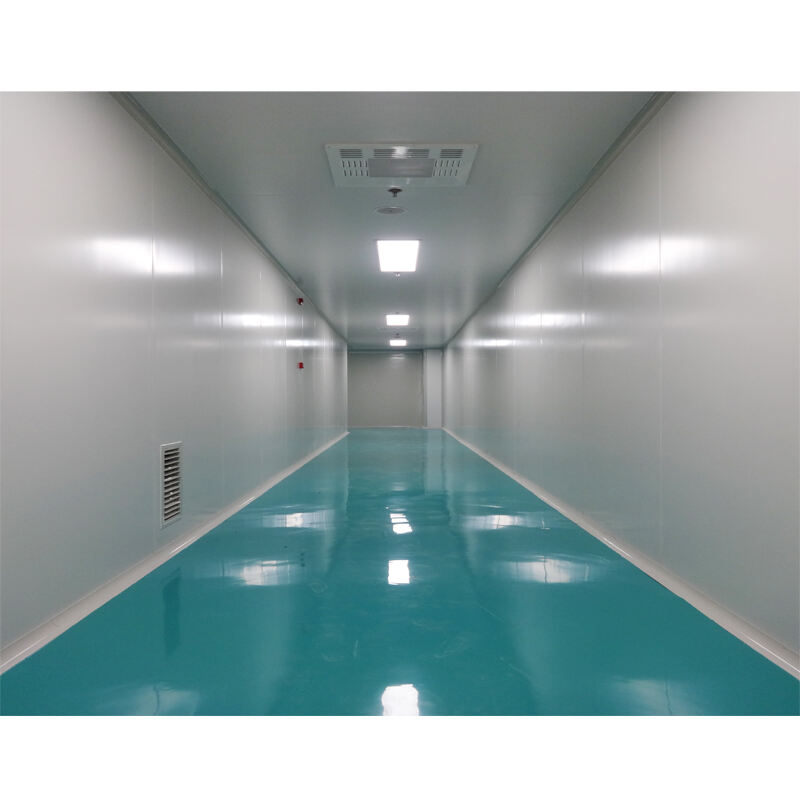

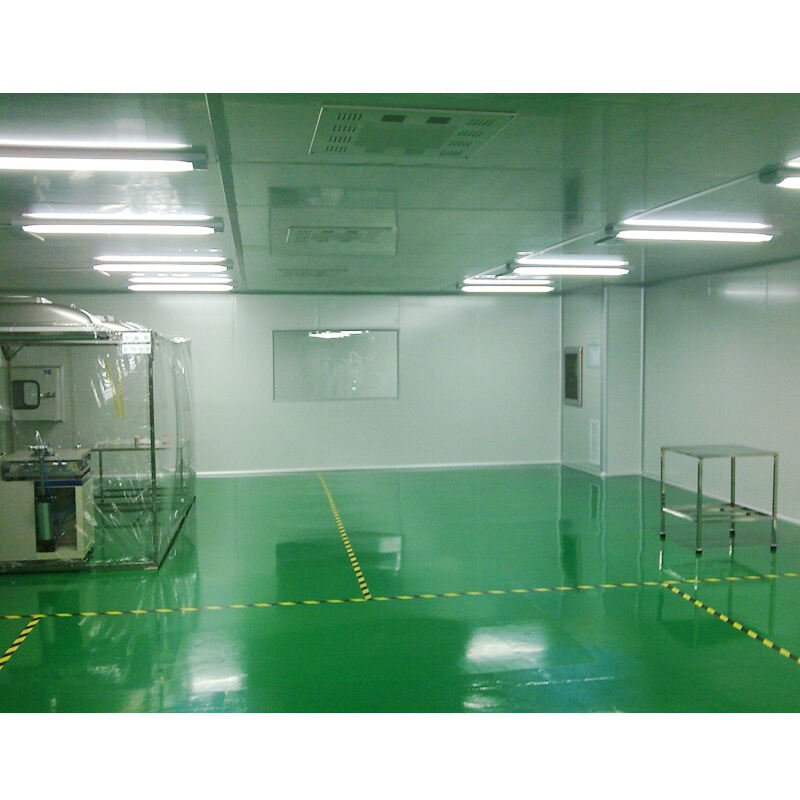

clean room ceilings

Clean room ceilings represent a crucial component in controlled environments, serving as an integral part of modern manufacturing and research facilities. These specialized ceiling systems are engineered to maintain strict environmental conditions by controlling particulate contamination, air pressure, temperature, and humidity. The design incorporates advanced filtration systems and specialized materials that prevent particle shedding while facilitating proper air circulation. These ceilings typically feature a modular construction that allows for easy access to utilities and mechanical systems housed above, while maintaining the integrity of the clean room environment. The panels are manufactured using materials such as powder-coated aluminum, stainless steel, or specialized polymers that resist corrosion and prevent particle generation. They often integrate sophisticated lighting systems, HEPA filters, and air handling components that work in concert to maintain the required cleanliness levels. The installation process involves precise sealing techniques to prevent contamination from the plenum space above, while special gaskets and gel systems ensure airtight connections between panels. These systems are designed to meet various cleanliness classifications, from ISO Class 8 to the most stringent ISO Class 1 requirements, making them suitable for diverse applications in pharmaceutical manufacturing, semiconductor production, biotechnology research, and medical device assembly.