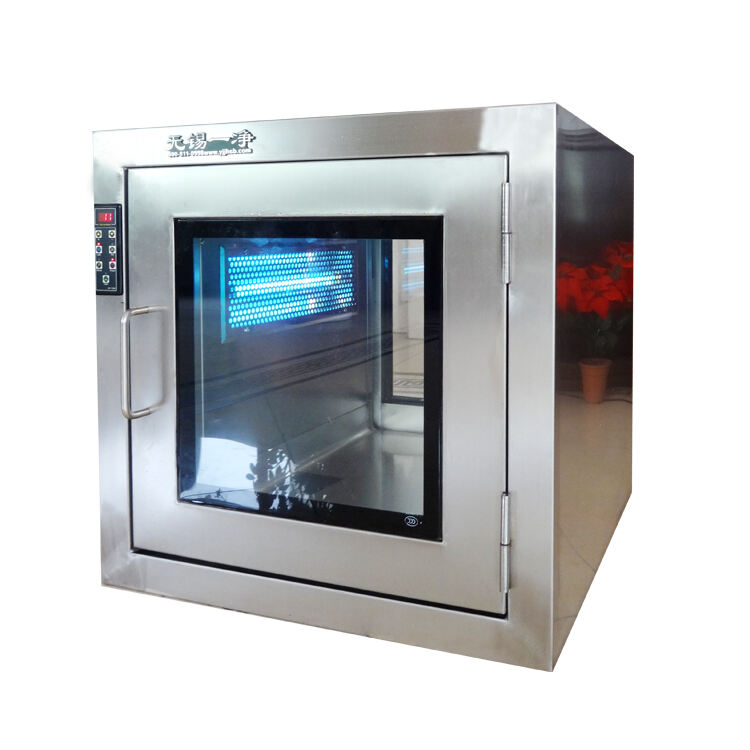

pass box clean room

A pass box clean room represents a crucial interface in controlled environments, serving as a sophisticated transfer chamber between areas of different cleanliness classifications. This specialized installation combines advanced filtration technology, precise pressure control systems, and robust construction to maintain the integrity of clean environments while facilitating the seamless transfer of materials. The system typically features interlocking doors with sophisticated electronic controls that prevent simultaneous opening, effectively minimizing cross-contamination risks. Modern pass box clean rooms incorporate HEPA or ULPA filtration systems that ensure optimal air quality during transfer operations. These units are constructed using materials that resist particle generation and are easy to clean, such as stainless steel and specialized polymers. The pass box can be customized with various sizes and configurations to accommodate different material handling requirements, from small components to large equipment. Many models include UV sterilization capabilities, real-time monitoring systems, and digital displays that provide instant feedback on environmental conditions. These systems find extensive applications in pharmaceutical manufacturing, semiconductor production, biotechnology research, and other industries where maintaining strict cleanliness standards is paramount.