types of pass box

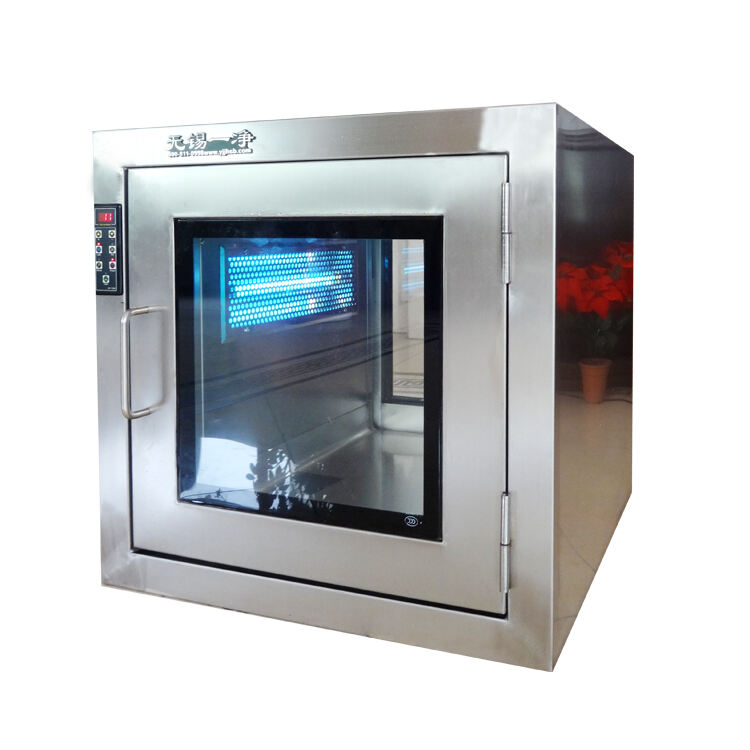

Pass boxes are essential components in cleanroom environments, serving as controlled transfer points between different cleanliness zones. There are several types of pass boxes, including mechanical pass boxes, static pass boxes, and dynamic pass boxes with air shower capabilities. Mechanical pass boxes operate with a simple interlock system, preventing simultaneous opening of both doors to maintain cleanliness levels. Static pass boxes provide basic transfer functionality with sealed doors and gaskets, suitable for less demanding applications. Dynamic pass boxes incorporate advanced features such as HEPA filtration, UV sterilization, and air shower systems to ensure maximum contamination control. These systems often include digital displays for monitoring environmental parameters, automated door mechanisms, and customizable operational settings. Pass boxes can be constructed from various materials, including stainless steel, powder-coated steel, or polymer materials, depending on specific application requirements. They are designed to accommodate different sizes and types of materials, from small components to large equipment, and can be configured with additional features such as pressure indicators, temperature monitors, and humidity sensors to maintain optimal transfer conditions.