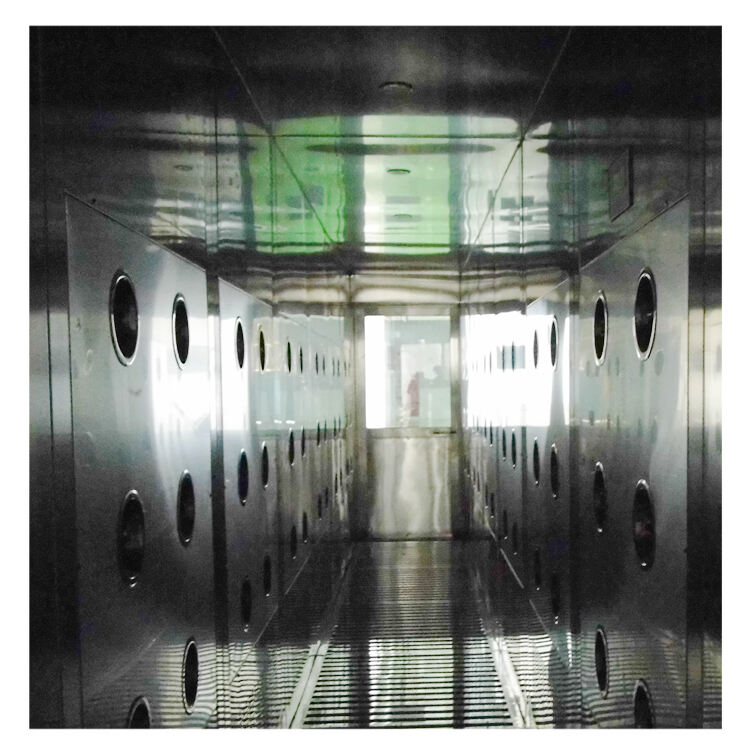

industrial air shower

Industrial air showers are advanced cleanroom technology systems designed to remove contaminants from personnel and equipment before entering controlled environments. These sophisticated units utilize high-velocity air streams, typically operating between 20-22 meters per second, to effectively dislodge and extract particles, dust, and other contaminating substances from clothing and surfaces. The system comprises multiple strategically positioned air nozzles that create a comprehensive cleaning zone, ensuring thorough decontamination from all angles. Modern industrial air showers incorporate HEPA or ULPA filtration systems that capture 99.97% to 99.999% of particles as small as 0.3 microns, guaranteeing optimal cleanliness standards. The air shower chamber features an interlocking door system that prevents simultaneous opening of entry and exit doors, maintaining the integrity of clean environments. Advanced models include automated sensors for operation, LED indicators for system status, and programmable cycle times to accommodate various cleaning requirements. These units are essential in industries such as pharmaceuticals, semiconductors, food processing, and biotechnology, where maintaining stringent cleanliness standards is crucial for operational success.