filter factory

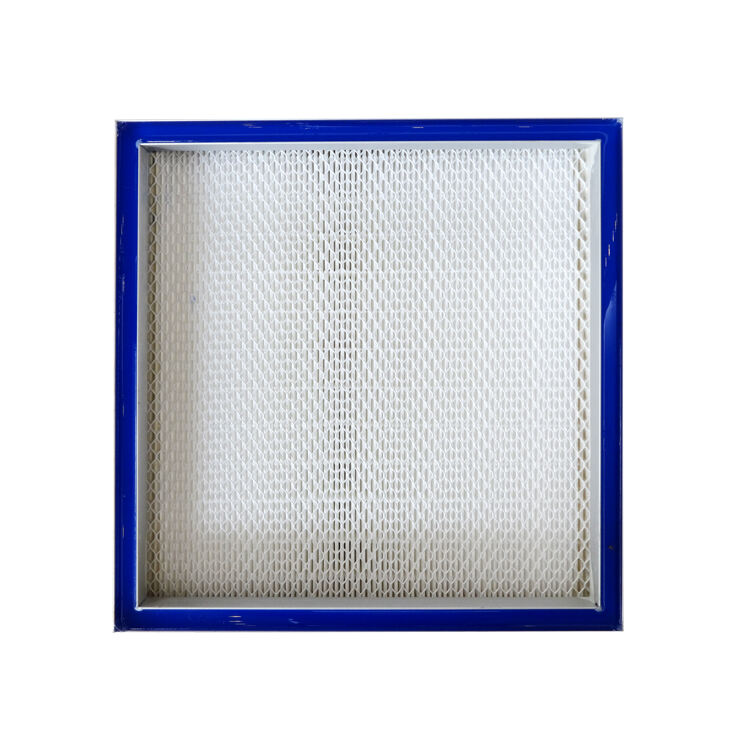

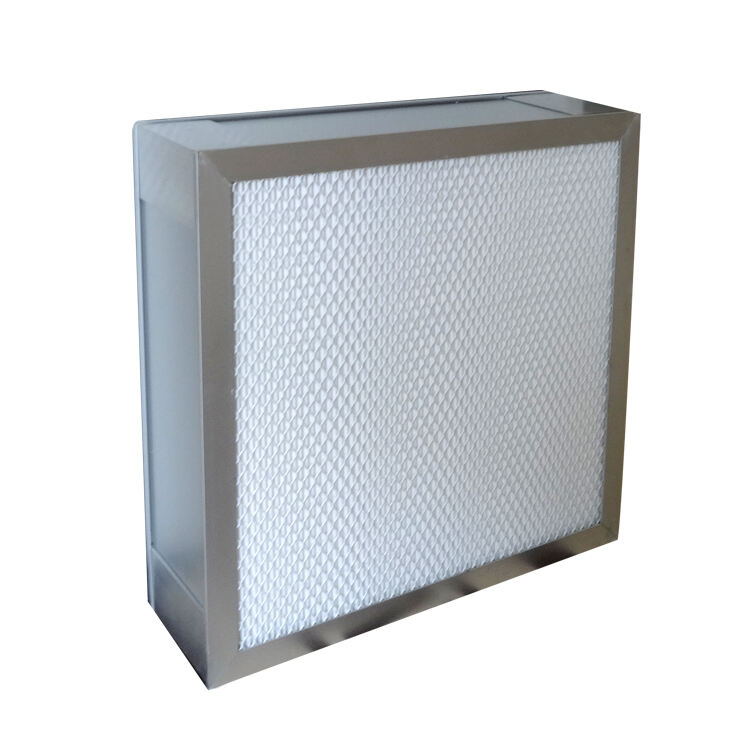

A filter factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality filtration solutions for various industries. These advanced facilities combine automated production lines, quality control systems, and innovative manufacturing processes to create filters that meet diverse application requirements. Modern filter factories utilize cutting-edge technology to manufacture products ranging from automotive filters and HVAC systems to industrial air purification solutions and water filtration systems. The facilities typically feature specialized production zones equipped with precision machinery for different filter types, including membrane filters, mechanical filters, and chemical filters. Quality assurance laboratories within the factory conduct rigorous testing to ensure each product meets industry standards and specifications. The production process incorporates sustainable practices, minimizing waste while maximizing efficiency through automated systems and smart manufacturing techniques. These facilities also maintain strict cleanliness standards and environmental controls to ensure product integrity and consistency.