filter air shower

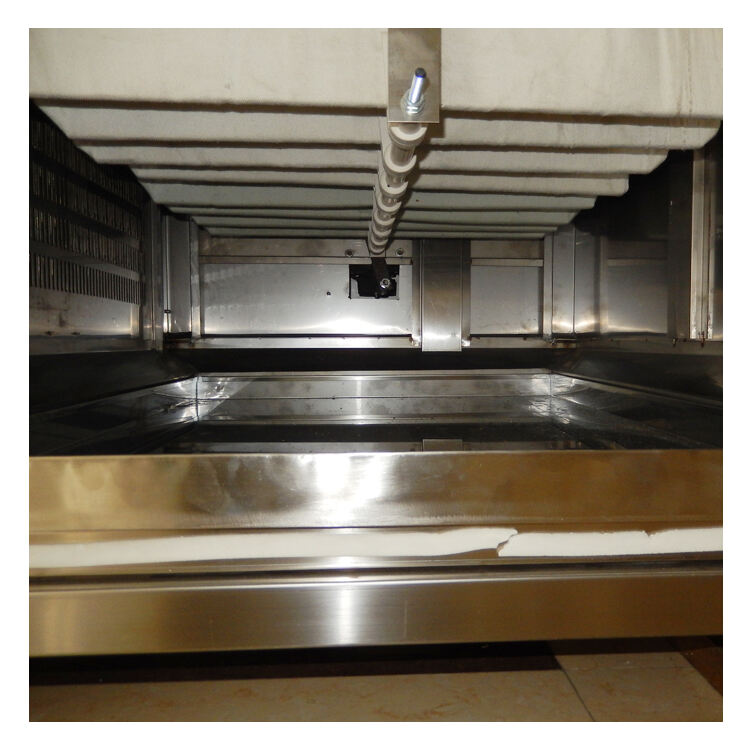

A filter air shower is an advanced cleanroom technology designed to maintain contamination control in critical environments. This sophisticated system creates a high velocity air stream that effectively removes particulate matter from personnel and equipment before they enter clean areas. The system consists of multiple high efficiency particulate air (HEPA) filters, strategically positioned air nozzles, and an automated control system. When activated, the shower generates a powerful stream of filtered air that dislodges dust, microparticles, and other contaminants from clothing and surfaces. The removed particles are then captured by the return air system and filtered out. Modern filter air showers incorporate advanced features such as interlocking door mechanisms, automated timing systems, and pressure differential monitoring. These systems are typically constructed using stainless steel or powder coated steel, ensuring durability and easy maintenance. The filtration efficiency typically reaches 99.99% for particles as small as 0.3 microns, making them essential for industries requiring stringent cleanliness standards such as semiconductor manufacturing, pharmaceutical production, and biotechnology research facilities.