dynamic pass box price

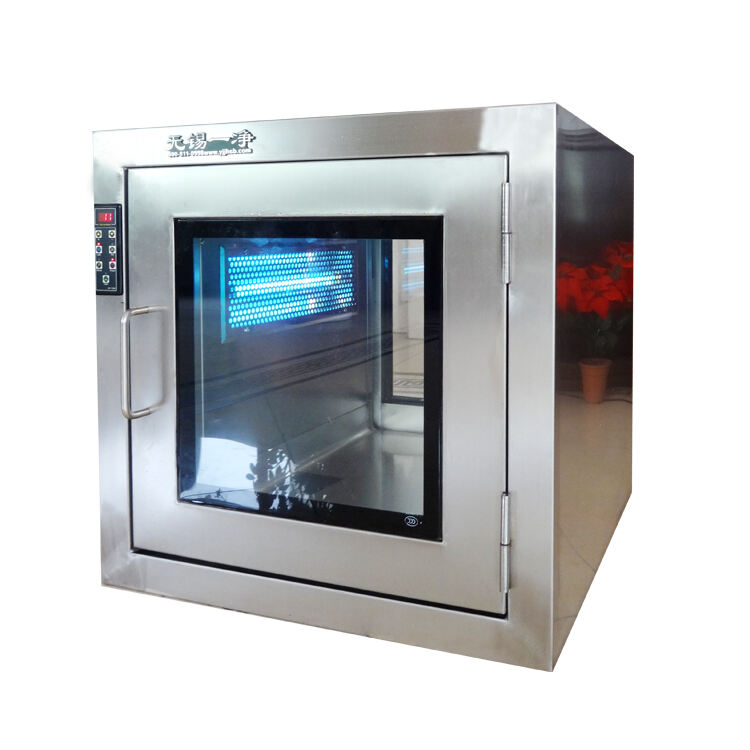

The dynamic pass box price represents a cutting-edge solution in cleanroom technology, offering automated transfer capabilities with real-time price adjustments based on market demands and operational requirements. This sophisticated system combines advanced material handling with intelligent pricing mechanisms, ensuring optimal cost efficiency while maintaining cleanroom integrity. The system features state-of-the-art HEPA filtration, programmable interlocking door mechanisms, and integrated pressure monitoring systems that work together to prevent cross-contamination during material transfer. The dynamic pricing component utilizes advanced algorithms to adjust transfer costs based on usage patterns, peak operational hours, and system demand, making it particularly valuable for pharmaceutical manufacturing, semiconductor production, and biotechnology applications. The system's robust construction typically incorporates stainless steel materials that meet GMP standards, while its user-friendly interface allows for easy operation and monitoring of both transfer operations and pricing adjustments. Enhanced with real-time monitoring capabilities, the system can track environmental parameters, transfer frequency, and pricing metrics, providing valuable data for operational optimization and cost management. This innovative solution represents a significant advancement in cleanroom technology, offering both operational excellence and financial efficiency in a single package.