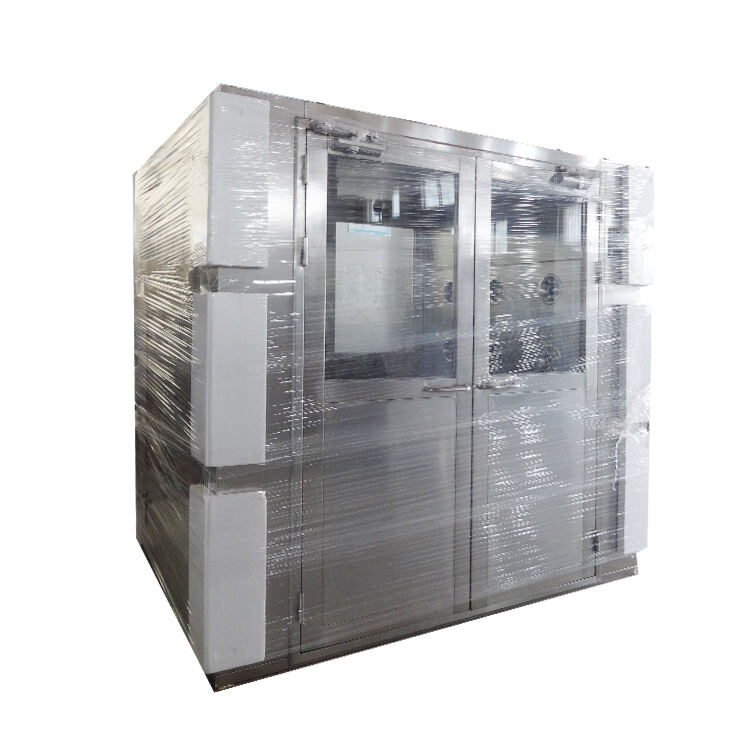

cargo air shower supplier

The cargo air shower supplier provides essential contamination control solutions for industrial and logistics facilities. This advanced system effectively removes dust, particles, and other contaminants from cargo containers, packages, and equipment before they enter clean or controlled environments. Operating through a sophisticated network of high-velocity air jets, the system creates a powerful air curtain that dislodges and captures airborne particles. The supplier offers customizable dimensions to accommodate various cargo sizes, from small packages to large shipping containers. The system incorporates HEPA filtration technology, ensuring 99.99% efficiency in particle removal down to 0.3 microns. The air shower features durable stainless steel construction, automated sensor-controlled operation, and user-friendly interface panels. Multiple nozzle configurations optimize airflow patterns for maximum cleaning effectiveness. Applications span across pharmaceutical manufacturing, food processing, electronics production, and other industries requiring stringent cleanliness standards. The system includes programmable cycle times, adjustable air pressure settings, and comprehensive monitoring capabilities for consistent performance.