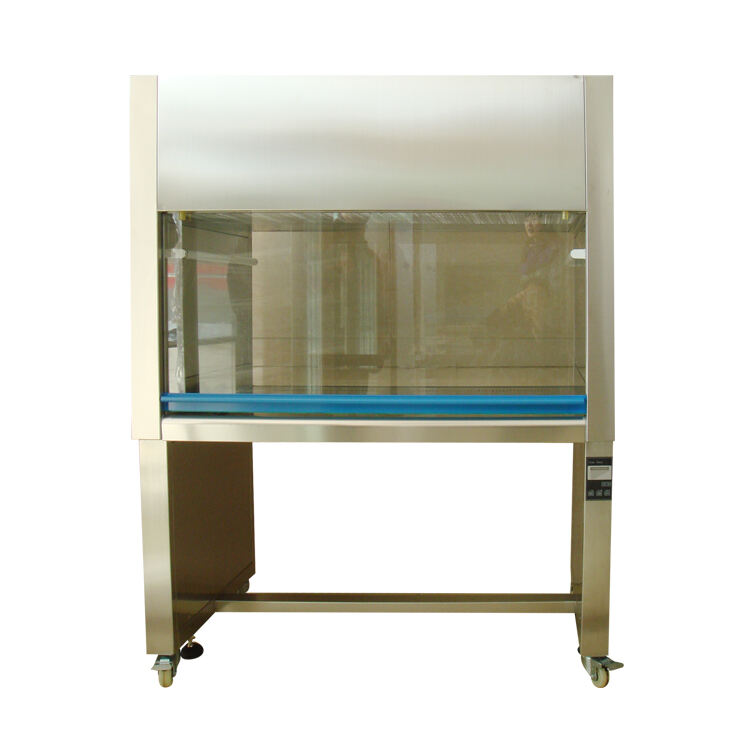

bàn sạch laminar

Bàn làm việc sạch dòng chảy là một thiết bị phòng thí nghiệm tinh vi được thiết kế để cung cấp không gian làm việc được kiểm soát, không có ô nhiễm, điều này rất cần thiết cho nhiều ứng dụng khoa học và công nghiệp khác nhau. Trạm làm việc chuyên dụng này tạo ra môi trường vô trùng thông qua hệ thống luồng khí được thiết kế cẩn thận, tạo ra dòng khí HEPA lọc đồng đều, dòng chảy tuyến tính. Hệ thống này loại bỏ hiệu quả các hạt bụi, duy trì tiêu chuẩn sạch ISO Class 5 hoặc Class 100. Bàn làm việc sạch thường có bề mặt làm việc bằng thép không gỉ, tấm chắn bên trong suốt và hệ thống chiếu sáng chuyên dụng để có tầm nhìn tối ưu. Hệ thống lọc chính bao gồm các bộ lọc sơ cấp và bộ lọc HEPA, có khả năng loại bỏ 99,99% các hạt từ 0,3 micron trở lên. Mẫu dòng khí laminar di chuyển theo chiều ngang hoặc dọc, tùy thuộc vào mô hình, tạo ra một hàng rào bảo vệ giữa khu vực làm việc và môi trường bên ngoài. Các đơn vị này được trang bị các điều khiển chính xác để điều chỉnh luồng khí, hệ thống giám sát hiệu suất của bộ lọc và thường bao gồm khả năng khử trùng UV để kiểm soát thêm sự ô nhiễm. Các bàn làm việc sạch hiện đại cũng có thiết kế nhân thể học, cài đặt độ cao có thể điều chỉnh và hệ thống vận hành tiết kiệm năng lượng, khiến chúng phù hợp cho việc sử dụng trong thời gian dài ở nhiều môi trường phòng thí nghiệm khác nhau.