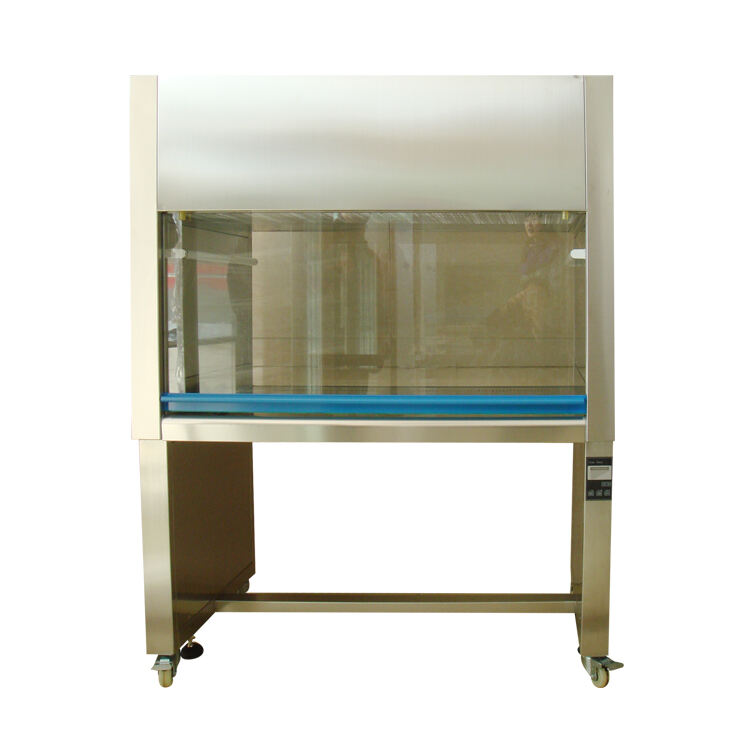

laminar flow clean bench

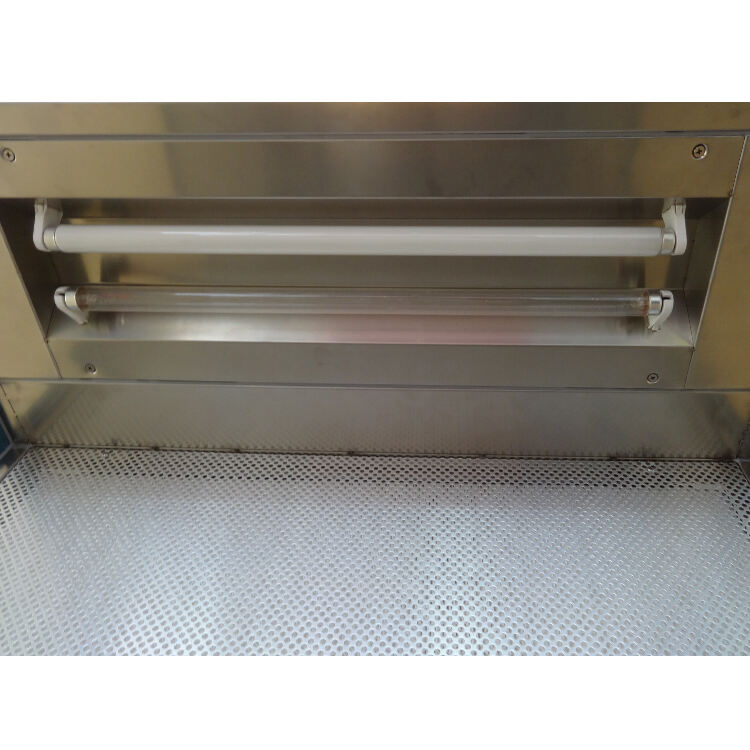

A laminar flow clean bench is a sophisticated laboratory equipment designed to provide a controlled, contamination-free workspace through the creation of a unidirectional airflow pattern. The system operates by drawing air through a HEPA (High-Efficiency Particulate Air) filter, which removes 99.99% of particles 0.3 microns or larger, creating an ultra-clean work environment. The filtered air flows uniformly across the work surface in a laminar pattern, preventing turbulence and maintaining a sterile workspace. This technology is particularly crucial in applications requiring strict contamination control, such as pharmaceutical manufacturing, microbiological research, and electronic component assembly. The clean bench features a transparent front panel that protects operators while allowing clear visibility and easy access to the work area. Advanced models include digital controls for airflow velocity adjustment, real-time monitoring systems, and UV sterilization capabilities. The workspace is typically constructed from stainless steel or other non-porous materials that resist bacterial growth and facilitate easy cleaning. These units are available in various sizes and configurations to accommodate different laboratory requirements, from compact benchtop models to full-size workstations capable of handling larger equipment and processes.