Technologia Filtrationis Progressiva

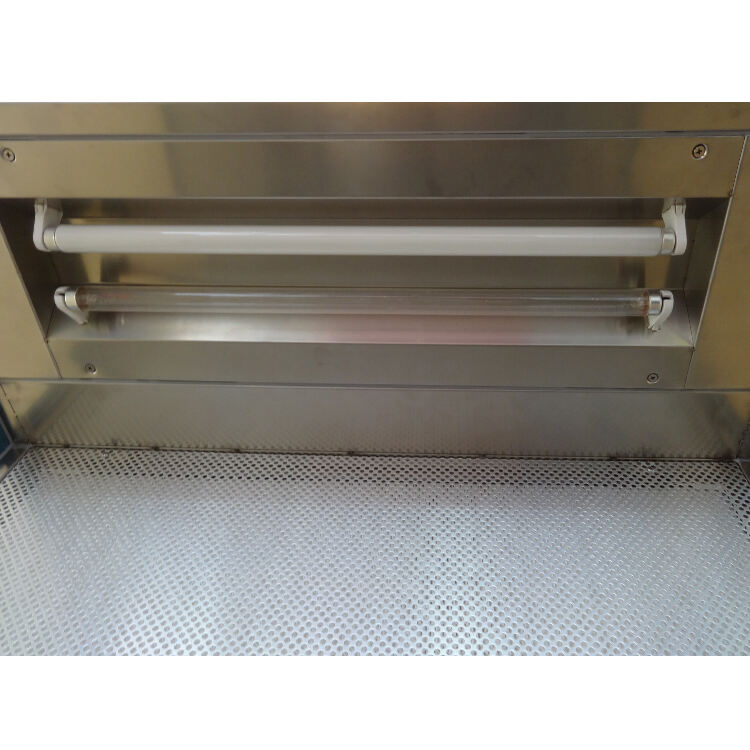

Funda mentis performance mensae aeris puri consistit in systemate filtratione elaborato, circa technologiam HEPA. Hi filtrantes mirabilem efficientiam ostendunt in captura particularum tam parvarum quam 0.3 micras, inter quas numerantur bacterii, pulvis, et alia contaminantia microscopica. Systema filtrationis usum facit approach multiformis, saepe praefiltrantes includens ad majores particulam capiendas et vitam principalem filtri HEPA prolongandam. Aeris fluxus ingeniose constructus certificatur ut aer filtratus uniformiter et in modo laminari moveatur, creans barriera invisibilis sed efficax contra contaminationem. Haec technologia continue monitoratur et conservatur per sensorem pressionis integratis et controles electronicos, constantem operationem securitatemque praebendo et usarios notificando quando necessarium est filtra mutare.