Meliorata Ratione Efficacitatis Energeticae

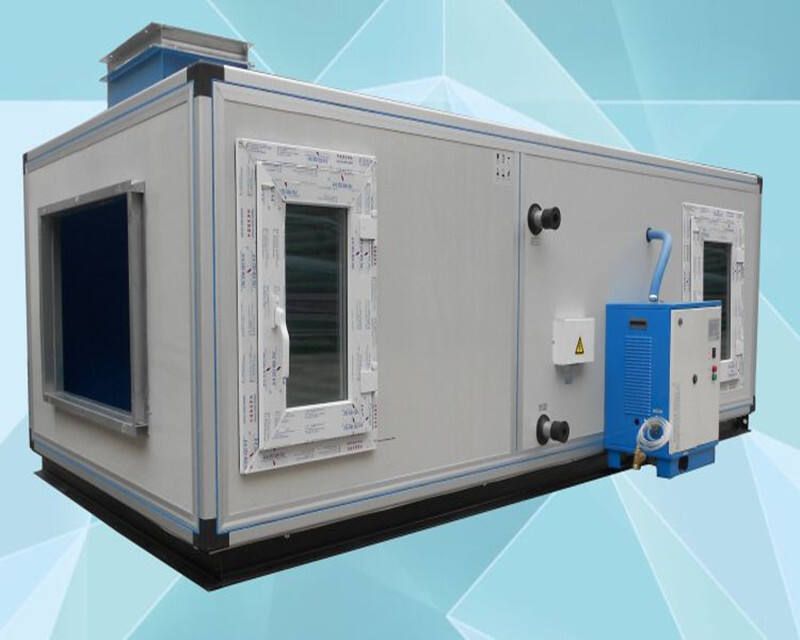

Ingenium praecipuum in structuris spiralis aerarium complectitur technologiam peritam transmutationis caloris quae efficacitatem energiae maximat. Optima structura lamminarum et dispositio tubulorum creant convenientem aequilibrium inter superficiem transmutationis caloris et resistentiam fluminis aeris, quod in praestantissimam operationem thermicam resultat. Spirales habeunt accurate rationatas interspatia quae vetant evagationem aeris dum velocitatem aeris optimam servant, ita ut efficacitas transmutationis caloris maxima fiat. Technica speciales ad meliorem distributionem refrigerantis, sicut sulci interni et striature externae, augmentant efficientiam totius systematis. Hoc designium melius potest parvos consumptus energiei usque ad viginti percentum comparatis cum spiralis vulgaribus, quod magnopere contribuit ad minuendos oneros operationis et impactum in ambientia.